Ⅰ. Overview

It was Karl Ziegler, a German chemist, who polymerized high-density polyethylene with the help of Zirconium-titanium complex catalyst, making it at low pressure and temperature for a linear result. HDPE is one of the names used for low-pressure polyethylene. It has a strong structure, is hard to damage and its melting temperature is set high, so the risk involved in production is usually low. The density of HDPE is 0.940g/cm3 or above and the crystallinity goes beyond 65%. With respect to LDPE and LLDPE, HDPE has the most intense tensile stress, more resistance against oxidant corrosion, greater impact toughness and good properties against seepage and corrosion. Most of the use of HDPE is in making films and sheets, blow molding and injection molding.

Ⅱ. Production Method

1) Gas Phase Method

It employs only one reactor to turn out full-density polyethylene, offering many product grades and up to 600,000 tons/year of maximum capacity. This patented catalyst is added into a vertical gas-phase fluid bed dryer reactor that has a larger top area, in the form of either solid powder or slurry. Raw material impurity must be controlled well and ethylene as well as the comonomer feeds require processing. The use of this design leads to lower amounts of powder resin particles. There is no requirement to use separation equipment for the gas and operating the reaction is done at mild conditions. You do not have to add any mixers, stirrers or other operating parts inside the reactor. Thanks to outstanding mixing in the reactor, the composition and temperature of the gas phase stay steady. However, the size of the reactor is large, so it takes a long time to switch to another product.

2) Slurry Process

HDPE is mainly manufactured using the slurry method which was developed and introduced earlier. The process is meant so that the polymer is fully suspended in the diluent. Based on the types of reactors, the slurry process consists of the stirred reactor slurry process and circular tube slurry process.

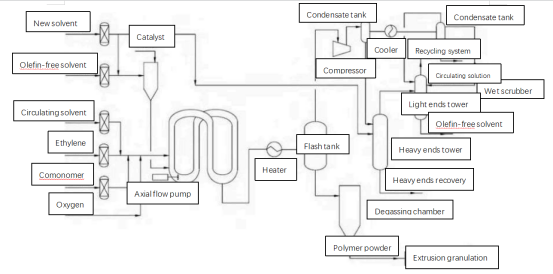

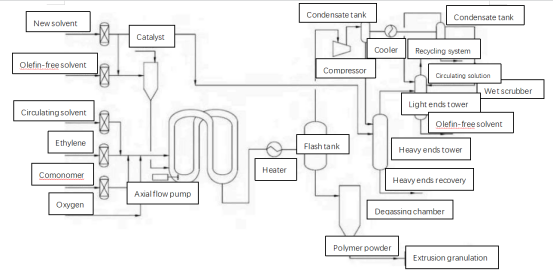

3) Solution Process

It takes less application of the solution process for HDPE production than the gas phase process or the slurry process. For solution synthesis, most often a stirred reactor is utilized. With the slurry method, ethylene enters the reactor and reacts with other materials and the polymer stays in a suspended state within the diluent, but with the solution method, the ethylene is directly dissolved in the solvent then reacts and the produced polymer is melted into a liquid. When separation is complete, you can directly turn the material into extruded and granulated products. The benefits of this solution include: quick respond of the reaction, short time for materials to stay in the reactor, short time for switching products, the produced polymer dissolves well in the solvent and the reactor’s capacity does not change. The solution method is often carried out at a high temperature and pressure, the processes tend to be quite long, there are more machines required and the overall costs are rather high.

Ⅲ. Conclusion

The company has created a system that covers stages ranging from processing raw materials to dried products in the HDPE industry range. Using a fluid bed dryer with an underlying heat exchanger in HDPE Granulation Projects for massive scale is successful, as it cuts and cuts on upgraded purity, making ensuring that hot air is equally distributed and vibration is regulated. Due to the frequent improvement in technology, Tianli Energy is bringing the HDPE industry to high-end and intelligent green standards, using efficient drying techniques to provide reliable Chinese solutions to customers worldwide.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK

UZ

UZ