Ⅰ. Overview

The chemical process runs when ammonia and sulfuric acid are introduced together and neutralized directly. People do not use it to communicate very much right now. Most often, sulfuric acid or ammonia water is used to trap by-products or exhaust gases produced in industries. The crystallization stage then uses an ammonia. It is possible to produce ammonium sulfate using gypsum (natural or phosphogypsum), ammonia and carbon dioxide. To make it, mix ammonium hydroxide with sulfuric acid, crystallize, use centrifugation to separate it and let it dry. In the neutralization method, you heat ammonia and sulfuric acid to around 100°C, whereupon the ammonium sulfate slurry formed is centrifuged and dried to obtain the ammonium sulfate product.

Ⅱ. Production Method

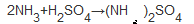

1) Neutralization Method

Ammonia and sulfuric acid are reacted inside a saturated crystallizer to form ammonium sulfate crystals and the crystals are separated using a centrifuge. The wet cake is put in a dryer to make the product and the liquid left behind is re-added to the saturated crystallizer. The reaction produces a lot of heat and that heat is used to remove the water from sulfuric acid or water plunged in specially to keep the mixture at the right temperature. For a saturated crystallizer under normal pressure, lots of air can be introduced into the reaction to take away the heat. Ammonia can be turned into ammonium sulfate by treating it with sulfuric acid using either coke-oven or coal gas and this method is also known as neutralization.

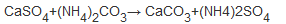

2) Gypsum Method

Mixing natural or by-product gypsum with ammonium carbonate produces calcium carbonate and ammonium sulfate solutions and calcium carbonate is set apart using filtration. The ammonium sulfate solution evaporates and crystallizes into solid form and it is then filtered using a centrifuge. To obtain the product, the filter cake is dried and the mother liquor is returned back to the evaporator. If there is not enough sulfur but plenty of natural or by-product gypsum nearby, this approach can deal with the sulfur problem in ammonium sulfate and the by-product calcium carbonate can be made into cement. The biggest disadvantage is that electricity hydroelectric plants use causes high energy consumption. If you want to produce the solid ammonium sulfate from the mother liquor formed during caprolactam, etc. production, the method stays the same as the second step mentioned.

Filtration, separation and concentration are some ways of extracting crystal products. By-products can also be used for the manufacturing of cement. Its negative aspect involves requiring a lot of energy.

3) Recovering sulfur dioxide from exhaust gas in sulfuric acid production to produce ammonium sulfate

Sulfur dioxide gas in the exhaust is treated with ammonia water to obtain ammonium sulfite and ammonium bisulfite solution which is thereafter acidified using sulfuric acid. Sulfur dioxide that is liberated can be liquefied to produce sulfur dioxide liquids or sent to the sulfuric acid plant to create more acid. Next, the rest of the ammonium sulfate solution is concentrated, crystallized and allowed to dry to make the product.

Ⅲ. Usage

A suitable nitrogen fertilizer (which is often referred to as fertilizer powder) enhances crop growth, fosters the health of fruit, increases the quantity of fruit, promotes resistance to disasters and it works well as base fertilizer, applied on top of soil and as a seed fertilizer. Salt reacts with it to create ammonium chloride, aluminum sulfate makes ammonium alum and boric acid allows its use in refractory materials. Putting it in the solution can boost the conductivity of the solution. It is involved in making food sauces, supplying nitrogen for growing yeast in making fresh yeast, acting as an assistant to acid dyes and assisting with deliming leather.

Ⅳ. Conclusion

Tianli enjoys many benefits when it comes to drying ammonium sulfate. For ammonium sulfate which is highly absorbent, we can use our drying method to remove moisture and reach the required moisture level. The company can provide you with everything you need for ammonium sulfate production such as designing the factory, making the equipment, drying and help with installation and commissioning, all the way to production support.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK

UZ

UZ