1. Salt-forming Reaction

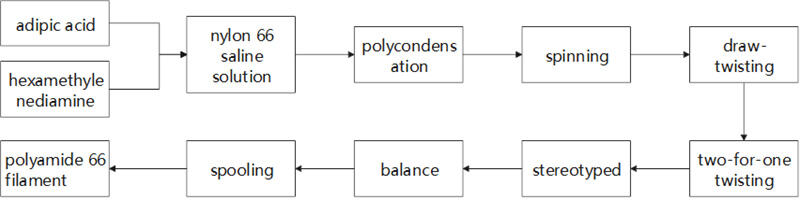

Each solution of adipic acid and hexamethylenediamine is prepared in water and then these solutions are added before being neutralized in the nylon 66 salt solution.

2. Polymerization Reaction:

Initially, aquatic solution is pressurized to separate monomers or prevent them from leaving as gases. The collected nylon 66 salt is transported to a evaporator, which is raised in temperature along the preheat and introduced into the reactor. Using a certain pressure and temperature, pre-convention is done to obtain a prepolymer with a polymerization degree of about 20.

3.Melt polymerization:

Upon leaving the decompressor, the prepolymer is vaporized and made completely dry in a three-roll sheeter, before it’s shaped into a film by a screw propeller and its molecular mass matches the set standard, indicating that polycondensation is over.

4. Pelletizing and cooling:

Once the polymerization reaction is done, the resin is turned into little granules by a pelletizer. After you pelletize the product, it is important to cool it fast so that the finished pellets do not stick together.

5. Post-processing:

They include drying and plasticizing. Since nylon 66 takes in moisture, it should be dried to prevent it from absorbing too much water; including plasticizers improves the material’s strength and elasticity for varied uses.

Tianli is now in charge of handling every step in the nylon industry from the production of raw materials to the products. Engineers of Tianli create custom solutions and install the required tools required to dry nylon 66 chip by selecting the right nitrogen purity and temperature that ensures that the products are always the same and high quality.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK

UZ

UZ