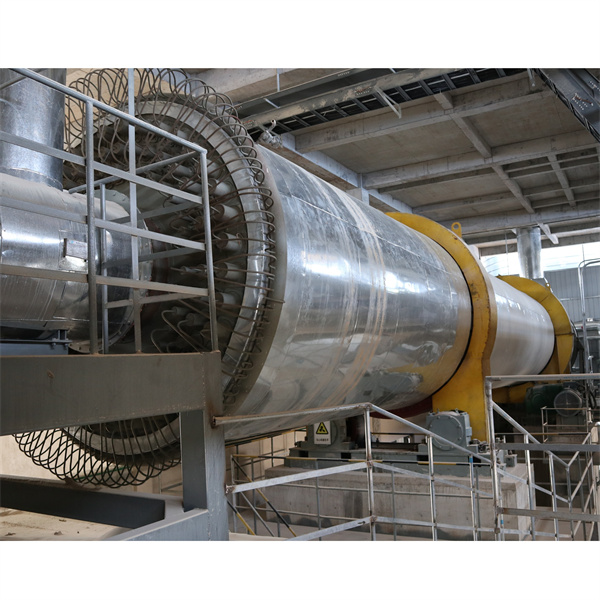

Direct heat rotary dryers are specifically designed industrial machines for drying purposes. These machines operate by heating materials in a bulky, spinning drum. The drum's rotation aids in the elimination of residual moisture, so everything comes out nice and dry. It is important to take a closer look at some of the key components of these machines that allow them to function effectively:

Agriculture: In the agriculture or farming sector, the farmers or food processing company utilize direct heated rotary dryer to dry the crop like grain, wheat, corn, etc. It also reduces the moisture content which is very important for final product quality improvement. For instance, moisture makes it easier for grains to spoil, so drier grains can be stored for longer periods of time without spoiling.

Chemical Manufacturing: Direct heat rotary dryers are also used in chemical manufacturing companies. They use it to dry powders and other materials. These entities can develop a more stable product by drying these substances, making it simpler, both to handle and transport. This is particularly critical when working with chemicals that may transform if too moist.

DIRECT HEAT ROTARY DRYER START-UP Climaterate2mad:Before you use a direct heat rotary dryer, you must follow a specific start-up procedure. This includes verifying that the fuel levels are adequate, the burner has been started, there are no leaks or other s, etc. It helps make sure that the machine will run efficiently and safely.

After the dryer is loaded with the materials, the drying process begins. During the drying process, you need to monitor the temperature and moisture content in the drum. Keep an eye on these levels so you can make necessary adjustments in the machine if required. If the temperature is too low, the material may not dry properly, and if it’s too high, it could damage the product.

A mining company was struggling to dry a particularly wet ore. Actually, this wet ore was a hassle on the transportation and storage phase. With the help of a direct heat rotary dryer, they were able to significantly lower the moisture content. This helped to produce a more stable product that was much less prone to transport and storage issues.

An agriculture company had quality issues with crops but were just too wet. Their high moisture content was negatively impacting the overall quality of their products. With the help of a direct heat rotary dryer, they learned how to dry their crops significantly more effectively. This didn't just lead to a better product at the end, but it also saved them time and energy with the drying.