And there is not just any ordinary machine, a fluid bed dryer working! This machine is really large and functions as an enormous oven. Many factories use it to manufacture various items using different chemicals. These types of kilns are made by a company called Shandong Tianli Company. These kilns are essential because they produce many types of items we use on a daily basis.

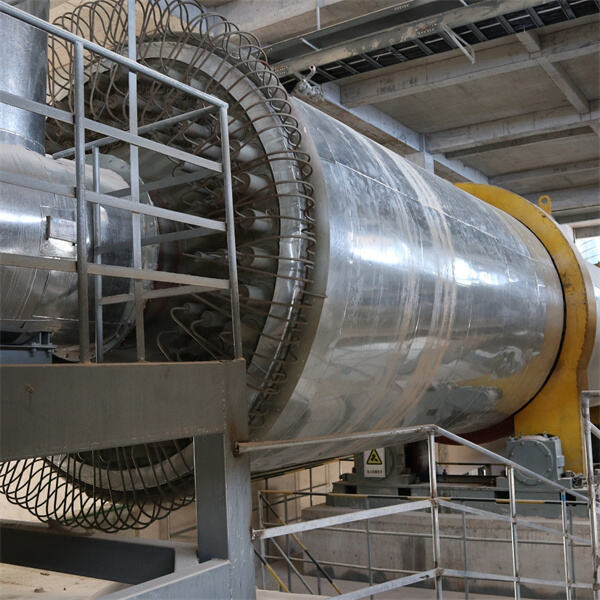

Now, what is a chemical rotary kiln? So picture a massive oven that keeps rotating and rotating. The rotation really mixes the materials inside the spinner. The kiln is very hot, to as high as 800 to 1800 degrees Celsius! That is very hot! This intense heat is what allows the chemicals inside to transform and react with one another. Industrys use these kilns in many different ways. For instance, they are used to manufacture cement, develop fertilizers for plants and make up different chemicals that form the processing unit in several products.

In a fluid bed dryer, there are various reasons to choose this type of equipment. The best part of using it is that it is superfast. The kiln heats to a temperature so hot that it can rapidly alter the chemicals and materials inside. Because of this speed, factories save time and money. The kiln is also able to synthesize a wide variety of chemicals and materials. It is therefore a very useful and versatile machine. A chemical rotary kiln can also be better for our environment as well. This helps recycle materials and products, allowing us to use items again rather than simply dispose of them.

It is a highly essential process that needs to be executed well for a chemical rotary kiln construction. Because they get so hot, these machines have to be pretty robust, and they can wear out. The kilns are usually made of really hard materials such as steel, brick, or ceramic. There are also special shapes and designs inside the kiln that help the materials get mixed and react properly. This design is critical with the aim of assuring that everything operates normally. And it's actually very well-insulated, so all the heat stays inside the kiln. This is key, because we want to ensure that heat doesn’t leak out into the adjacent area.

Understanding how a chemical rotary kiln works is quite simple and fascinating. First, workers add in the materials and chemicals that they’re looking to react or change into something else into the kiln. Once everything is in, they turn the kiln on, which then begins to spin around. Because as the kiln spins around, it will heat up to those really intense temperatures and the chemicals and materials in there will react and change. This stage is necessary for producing those new products. The kiln rotates and keeps the materials inside mixing constantly, which ensures everything is reacting properly. Lastly, once the reaction is done, the workers remove the finished products and cool them down before using them.

It is because of which that a chemical rotary kiln can prove to be a boon to the factories for making the processes stronger and more capable with utmost output and with eco-friendly working. It does this in part by finding new uses for scrap materials. To assist, if there are leftovers from one process that can still serve a purpose, workers are able to throw them into the kiln and allow it to undergo another transformation into innovative creations. Here is an excellent way to eliminate waste! Moreover, the extreme heat of the kiln can potentially serve as a source of energy or power for other parts of the factory. This ends up saving even more money and the need for auxiliary energy sources. It is versatile, meaning that the same kiln can accommodate a variety of reactions, processes, and materials. This enables a factory to manufacture a wide variety of products that is very useful.

Tianli is a luxury brand-building enterprise in Shandong Province and a Shandong Famous Brand. Tianli is "The First (Set) of chemical rotary kiln Enterprise of Shandong Province, Single Champion Enterprise of Manufacturing Industry of Shandong Province, etc. 2. Advantages of project experience that has been successful: Tianli has undertaken nearly 3, 000 projects in the new material, energy, petrochemical, biochemical, metallurgical, and other industries and has gained a wealth of project knowledge.

1 Quality Control: A mature quality system is crucial to ensure the quality of the products 2 Timeline guarantee: Tianli has a 70 000 square meters of equipment manufacturing facility with an chemical rotary kiln of five hundred tons It is able to adapt production plans to demands of customers and maintain the timeline 3 Our equipment can meet the high-end market requirements and guarantee quality by selecting items that are precisely 4 Innovation in technology: concentrate on innovation and research in the field of technology constantly develop new technologies and improve manufacturing processes and ensure market competitiveness

Tianli owns more than 240 patents, as well as several chemical rotary kiln and products, each with their own intellectual property rights. 2. Achievements: Tianli has won 1 Outstanding Achievement Award of the "Ninth Five-Year Plan" National Key Science and Technology Research Plan The award was 1 first prize, four second prizes, and 3 third prizes in Shandong Province Science and Technology Progress Award; Tianli participated in the creation of the national standard and also wrote 5 related books and monographs. 3. Tianli has RD center as well as an innovation system that creates an unbroken cycle of technological breakthroughs, engineering products to massive sets of drying equipment that can be used for wide applications and promotion, which ensures the company's sustainable development.

1. Tianli is the most renowned company in China's drying industry chemical rotary kiln high- and new technology enterprise from "Scitech Reform and Innovation demonstration", Shandong Gazelle Enterprise and others; 2. Tianli has the RD center as well as an entire team of more than 150 engineers. It has the Class A design center with an engineering design capability that is strong; 3. Provide customers with high value-added services, consider and solve issues from the perspective of customers. Provide solutions to customers' needs in technology development, pilot test design, process design, manufacturing of products, installation and commissioning, after-sales services and technology upgrades; Tianli has been involved in more than 3000 successful projects in China.