An electric furnace with a rotary kiln has many benefits, along with Shandong Tianli's product flash dryer machine. It is also one of the best things about this product as it works with electricity. For our mother earth electricity is a non polluting clean form of energy, which can prevent pollution levels to be on rise. This in turn leads to cleaner air and a healthier environment for all whenever these furnaces are utilized by companies.

Another key advantage is the rotary kiln electric furnace can produce very high quality metal. Heating metal to white-hot temperatures in the furnace helps eliminate impurities. Impurities are the materials which either render the metal weak or less useful. The Furnace removes these impurities, generating the clean and robust metal excellent for fabrication.

The rotary kiln electric furnaces produce high-grade refractory metals in a truly unique process, same with the centrifugal spray dryer from Shandong Tianli. Well, to begin with, they require electricity so they can heat the metal up until it is a liquid between 2 very hot dogs. At this point in time, minor scraps of the metal melt and any impurities will float to the top allowing it to be scooped away. It is called smelting and this process is very crucial as in results to purify the metal by cleaning.

When these impurities are removed, the purity of the metal increase. The metal is then cooled by the furnace. The cooling process is a vital step that returns the molten metal into solid form. That metal is now a solid, strong material which can be shaped for many different purposes from tool-making to construction and mechanical uses.

Most companies have begun using rotary kiln electric furnaces because of their plethora and usefulness they provide, along with Shandong Tianli's product drum rotary dryer. Such furnaces help in the production of metal free from impurities and far superior to that generated through other means, by companies. As a result, they can produce more reliable and longer-lasting products.

Additionally, rotary kiln electric furnaces offer better efficiency compared to other metal creating alternatives, as well as the double drum dryer from Shandong Tianli. Companies can save on energy costs due to this efficiency. That helps them produce high-quality metal and keep their businesses in operation at a substantially lower electricity cost.

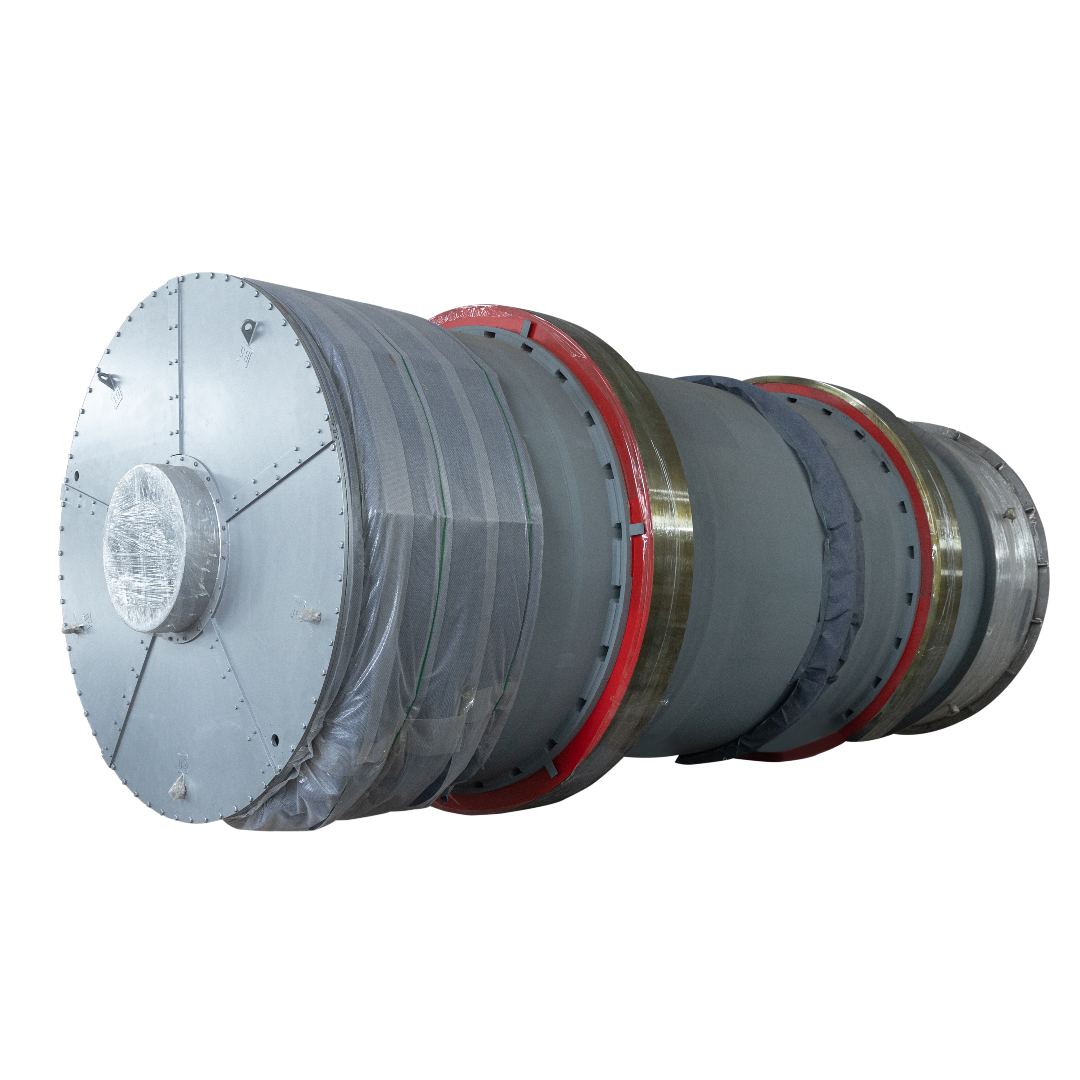

Rotary kiln electric furnaces, as you might imagine from the name, are a type of specialized furnace that provide high temperature to carry out certain chemical processes, also the Shandong Tianli's product such as drum rotary dryer. But unlike other types of features or devices fed with electricity (like washing machines and tools that contain an electrical cable) there is more than meets the eye about what makes up these rotary parrots. which technology behind them can be confusing even when one looks at it closely based on our modern understanding? They must make a particular control so the furnace can spin at that certain velocity — and engineers do work on this aspect, as i recorded many line changes with feedback from an engineer. Heating the metal correctly is crucial, and that too at right speed. This makes sure the metal is heated to the correct temperature and then carefully cooled.

Tianli holds more than 240 patents and a number of fundamental technologies and products with the rights to their intellectual property. 2. Achievements: Tianli has won 1 outstanding Achievement Award of the " Rotary kiln electric furnace" National Key Science and Technology Research Plan was awarded 1 first prize, 4 second prizes, and 3 third prizes at the Shandong Province Science and Technology Progress Award; Tianli participated in the creation of the national standard, and also published 5 related monographs and books. 3. Tianli's RD Center and Innovation System create a positive cycle from the latest technological advances to engineering products and huge sets of drying equipment that are complete. This will ensure the continued growth of the company.

1 Quality Control: A solid quality system is necessary in order to guarantee the quality of the products 2 Schedule guarantee: Tianli's 70 000 square meters production facility can produce the capacity to process each year Rotary kiln electric furnace which enables it to tailor production plans to meet the needs of customers 3 Quality assurance: With the precision of our selection process our equipment can ensure that product indicators are accurate and can meet the requirements of a high-end market 4 Technological innovation: focus on research and development in technology and innovation continually develop new technology improve production processes and keep market competitive

Tianli has a high-end branding and marketing enterprise in Shandong Province and a Shandong Famous Brand. Tianli is "The First (Set) of Technical Equipment Manufacturing Enterprise of Shandong Province, Single Champion Enterprise of Manufacturing Industry of Shandong Province, Rotary kiln electric furnace. 2. Advantages of project experience that has been successful: Tianli has undertaken nearly 3000 projects in the area of new materials, energy as well as biochemical, petrochemical metallic and other fields, and has built up a vast project knowledge.

1. Tianli is the top company in China's drying industry, national high and new technology enterprise of "Scitech Reform and Innovation demonstration", Shandong Gazelle Enterprise and more; 2. Tianli includes the RD center, as well as around 150 engineers. The center also houses the Class A design center with the ability to design engineering with a Rotary kiln electric furnace of precision; Deliver high-quality and cost-effective services to customers, including research and development and pilot tests, design of processes, manufacturing, installation of products and commissioning as well as after-sales and support services. Tianli has been involved in more than three hundred successful projects across China.