Did you ever wonder why your breakfast cereal does not get soggy in milk? Or the way you ingest your medicine in pill form? Well, the solution to both of these problems is spray drying. Spray drying is a unique process that converts liquids into powders. The process can be mimicked with a pilot scale spray dryer, so sometimes it is referred to as the small-scale production of nanoparticles. This can become increasingly necessary for several businesses.

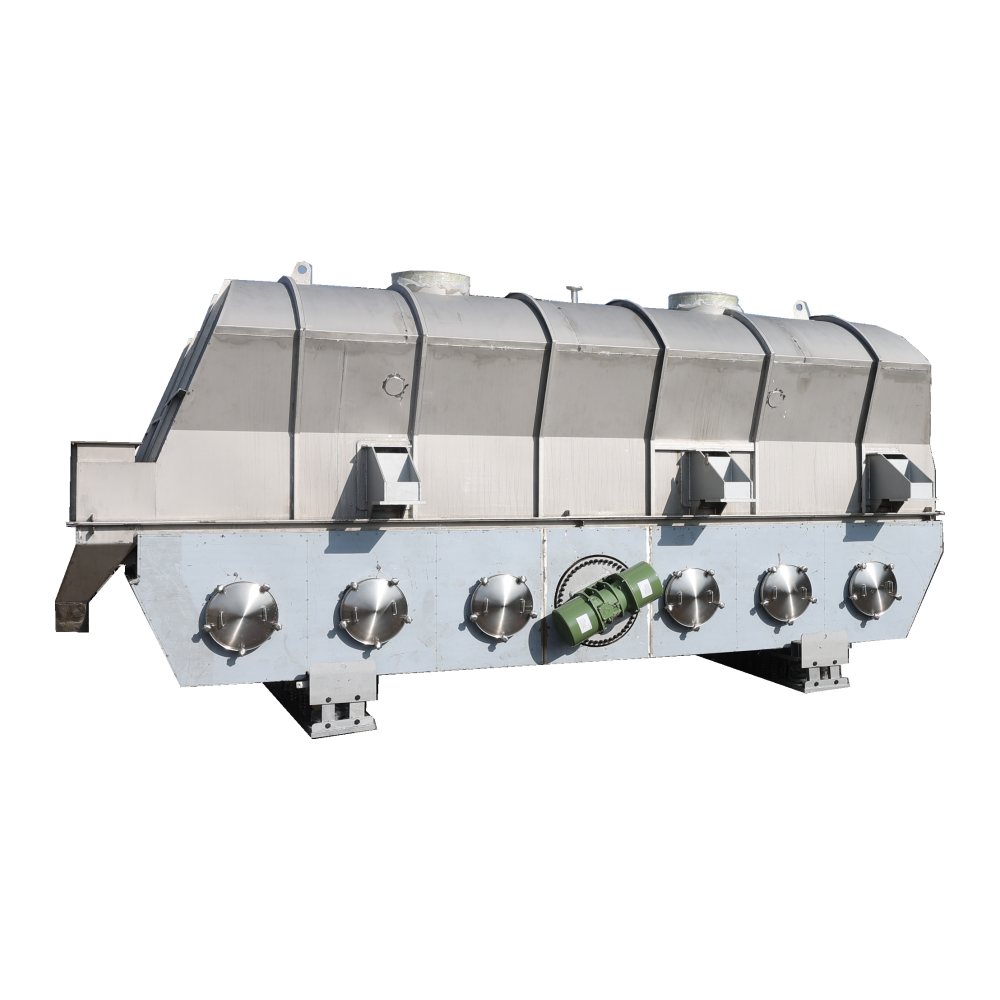

A pilot scale spray dryer is a machine which permits organizations to experiment and manufacture their liquid products, just like the Shandong Tianli's product called fluid bed dryer cost. That small amounts of liquid turns to powders dry This process is good because it will save the time and money of businesses as well. They will test their models first with small quantities to see what works best and then create a lot of them. That way it can stop wasting resources one more time, and the result will be better too.

By using a pilot scale spray dryer companies get the advantage to work more perfection in production of their products so whether it is sodium chloride or anything else, they can use this with approachable manners. Since it is a smaller machine there can be improved testing and idea innovations. So businesses can catch problems before they occur when manufacturing many units of their product. Now if you fix these problems at an early stage the rest of production tends to go nice and smooth.

Furthermore, Mature technology is applied to the design of industrial spray dryers, as well as the rotary paddle dryer produced by Shandong Tianli. For instance, some machines employ special tools known as atomizers which help in generating small liquid droplets. This serves to dry the liquids more evenly, and important if you wish a quality product. Improved control of the drying process helps these companies design their better products more effectively.

A pilot scale spray dryer also helps companies create larger quantities of their product, identical to Shandong Tianli's product centrifugal spray dryer. This could equate to increased profits and sustainable opportunities for expansion of the business. Choosing the right machines and technology early on could determine how successful companies will be in the long-run. So they can produce more products and have room to grow their business in the future.

Pilot as well enables companies to control key parameters such temperature and pressure very precisely, same with the rotary kiln cooler manufactured by Shandong Tianli. With each of these in place, a business can make sure that the product is dried just right. The remaining time was due to the need of carefully monitoring progress, necessary not only for validation but also ensuring specifications can be met and maintain desired quality/texture in order to delight consumers.

If businesses can design even better, they could always invest in new pilot scale spray drying systems to make sure that their products come out as perfect featuring every single detail, also the Shandong Tianli's product such as rotating dryer. Many of these systems offer state-of-the-art technology; spray dry fluid beds. Businesses can use the new method of drying to have more control over their product during this step and produce products at an even higher quality level.

1. Tianli has a number of Pilot scale spray dryer and products that are protected by exclusive intellectual property rights and currently holds more than 240 patents. 2. Achievements: Tianli has won 1 Outstanding Achievement Award of the "Ninth Five-Year Plan" National Key Science and Technology Research Plan was awarded one first prize, four second prizes and 3 prizes in Shandong Province Science and Technology Progress Award; Tianli participated in the formulation of one national standard and also wrote 5 related books and monographs. 3. Tianli's RD Center and Innovation System create a positive cycle from technological achievements to engineering products and huge sets of drying equipment that are complete. This will ensure the continued growth of the business.

Tianli has a high-end branding and marketing enterprise in Shandong Province and a Shandong Famous Brand. Tianli is "The First (Set) of Technical Equipment Manufacturing Enterprise of Shandong Province, Single Champion Enterprise of Manufacturing Industry of Shandong Province, etc. 2. Benefits of having a successful experience in project: Tianli has undertaken nearly 3, 000 projects in the new material, energy as well as Pilot scale spray dryer, petrochemical industrial metallurgical and others, and has accumulated rich project experience.

1. Tianli is the largest enterprise in China's drying industry National high- and new technology enterprise from " Pilot scale spray dryer and Innovation demonstration", Shandong Gazelle Enterprise, etc. 2. Tianli includes the RD center as well as the team of over 150 engineers. The center also houses the design center of Class A with strong engineering design capabilities; 3. Provide customers with high value-added services, consider and solve problems from the perspective of customers, and provide services to customers in technology development, pilot test and process design, as well as manufacturing of products, installation and commissioning, after-sales services and technology upgrades. Tianli has completed more than 3, 300 successful projects in China.

1 Quality Control: A solid quality system is necessary in order to guarantee the quality of the products 2 Schedule guarantee: Tianli's 70 000 square meters production facility can produce the capacity to process each year Pilot scale spray dryer which enables it to tailor production plans to meet the needs of customers 3 Quality assurance: With the precision of our selection process our equipment can ensure that product indicators are accurate and can meet the requirements of a high-end market 4 Technological innovation: focus on research and development in technology and innovation continually develop new technology improve production processes and keep market competitive