Powder is a fine material used in a number of areas, including food products, medicine, and chemicals. Many industries use this because it can be used to create all types of products. However, powder can, at times, be difficult to maintain and transport and use correctly. That's why some companies have developed a way to transform powders into coarser pieces called granules. They accomplish this through a process called fluid bed dryer working.

One such process is agglomeration spray drying to convert powder into granules. First, the powder is put under heat and pressure. Simultaneously, a liquid is introduced to the blend. This liquid holds great significance as it aids in binding the microscopic powder particles. When the powder clumps up, it becomes larger pieces, called granules. Then, the heat dries these granules, hardening, and strengthening them so that they can be used. Lastly, the remaining powder which didn’t get incorporated into the granules is separated. This leaves granules far easier to process and use as the waste.

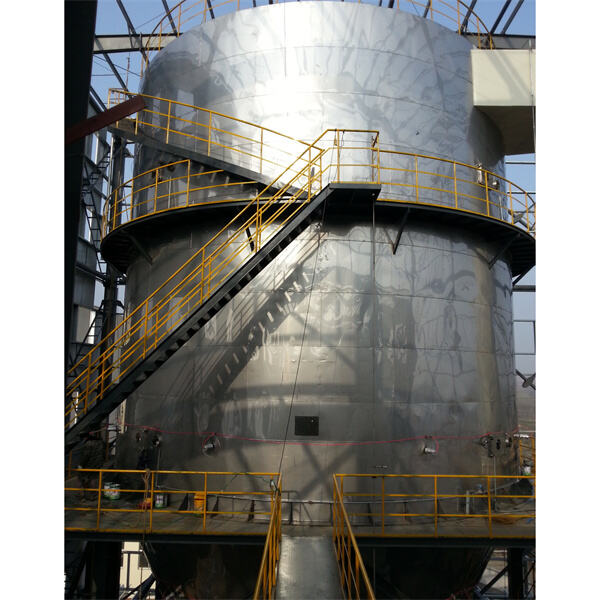

Chongqing Tianli is a company that specializes in fluid bed dryer. We know how to make good granules, and we do it well. At our facility, we are using high-end techniques to make sure that the granules we create remain nice and even. Various industries find use for these granules. To do so, we parametrize critical parameters such as temperature, moisture, and flow rate of materials during the process. This ensures precision with granules every time. We also have advanced machines that allow us to produce a greater amount of granules while using fewer resources. Doing this helps us to save money and reduces pollution, thus is good for the environment.

Agglomeration spray drying has many advantages. The powder form does, nay, have one major advantage: Granules are far more manageable, storeable, and easy to tip at rack than powder. Granules ensure less spilling or messes when you have one. Granules also have a longer shelf life because they don’t absorb moisture as easily as powder does. They are worked up to data best to October 2023. Granules also mix and dissolve better in liquids without the formation of lumps, which is normally considered an advantage for applications in cooking or medicines.

However, agglomeration spray drying also presents certain limitations worth considering. Especially if this requires special machines or materials to even begin with, the process can be rather costly and time-consuming. Additionally, not all powder types can be used for this process. Some powders have different chemical or physical properties that render them not easily granulated through this method.

If you are considering agglomeration spray drying for your industry, Shandong Tianli is at your service. We have got a comprehensive guide for you to get a better picture of the process. We will consult and advise you whether agglomeration spray drying is the perfect fit for your product. If so, we will give you recommendations on the best methods and tools that match your specific requirements. Further, we provide a whole range of testing & development services which you can rely on to meet all your quality, yield, cost & environmental impacts.

1. Brand advantages: Tianli's brands include "Shandong Famous Brand", and Tianli is a agglomeration spray drying of Shandong Province" that has a high standing in the business. Tianli is "The First (Set) of Technical Equipment Manufacturing Enterprise of Shandong Province, Single Champion Enterprise of Manufacturing Industry of Shandong Province, etc. 2. Advantages of project experience that has been successful: Tianli has undertaken nearly three thousand projects in the fields of material, energy as well as biochemical, petrochemical metallurgical and other industries, and has gained a wealth of project experience.

Tianli, the leading enterprise of China's drying industry is a major national high-tech company, Shandong Gazelle Enterprise and an example enterprise for "Scitech Innovation and Reform". Tianli is home to an RD Center and close to 150 engineers. The company also has a Design Center of Class A that has excellent capability in agglomeration spray drying design. 3. Provide customers with high-value services, focusing on and solving problems from the perspective of customers, and provide assistance to customers in the areas of technological development, pilot test, process design, manufacturing of products, installation and commissioning, after-sales service as well as technology upgrades. 4. Tianli has been able to successfully complete more than 3, 300 projects across China.

1. Tianli has a variety of products and core technologies with distinct intellectual property rights and currently holds over 250 patents. Tianli received the Outstanding Achievement Award for the "Ninth Five Year Plan" National Key Science and Technology Research Plan. It also took home the first prize, as well as agglomeration spray drying and three third prizes in the Shandong Provincial Science and Technology Progress Award. Tianli was involved in the development and publication of 5 books and monographs related to the standard. 3. Tianli's RD Center and Innovation System form a virtuous circle of technological advancements, engineering products, as well as large-scale sets of drying equipment that are complete. This ensures the sustainable growth of the business.

1 Quality Control: A stable quality system is agglomeration spray drying to ensure the high-quality of products 2 Schedule assurance: Tianli's 70 700-m2 manufacturing facility for equipment has the capacity to process annually 5 500 tonnes allowing it to optimize production plans in line with the demands of the customers 3 Assuring quality: by making an exact selection our equipment can ensure that product indicators are accurate and satisfy the needs of the market with high-end quality 4 Technology-driven innovation: Focus on RD in the field of technology innovation and constant development of new technologies Improve processes for production and ensure competitiveness