Calculation of Sludge Calorific Value and Parameters for Using Incineration Heat for Self-Drying

1. Sludge Calorific Value Calculation

The mud for ash is reflected in dry-based calorie value of the heat mud released by complete combustion of organic matter. The calculation formula for dry-based calorie value of mud is as follows:

Q=2.5×105×(100Pv−5)

- Q: Dry-based calorific value of sludge (J/kgDS, where DS denotes dry solid).

- Pv: Content of organic matter in dry sludge (%).

When the moisture content is w, the calorific value of the sludge is calculated as: Qw=Q×(1−w)−q×(w+9wh)

- Qw: Calorific value of sludge at moisture content w.

- q: Latent heat of vaporization of water at 100°C (2260 kJ/kg).

- wh: Hydrogen content in dry solid sludge (taken as 2%).

Example: For sludge with 30% moisture content and 40% organic matter content: Q=2.5×105×(100×40%−5)=8.75×106J/kg=8750kJ/kgQw=8750×(1−30%)−2260×(30%+9×2%)=6125−1084.8=5040.2kJ/kg

The organic matter content in domestic sludge generally ranges from 30% to 65%.

2. Calculation of Minimum Moisture Content for Self-Sustained Combustion

It is generally considered that sludge can self-sustain combustion when its calorific value exceeds 800 kcal/kg (equivalent to 3348 kJ/kg) and can enable heat recovery when exceeding 1100 kcal/kg. Assuming the organic matter content remains 40%, the moisture content w1 is calculated using the above formula:3348=8750×(1−w1)−2260×(w1+18%)w1=45.4%

Reasons for High Calorific Value in Low-Temperature Sludge Drying

1. Dehumidification: A heat pump sets the temperature low to reduce moisture in the air which evaporates a lot of water from the mud.

2. With drying at 75 ° C, organic matter is maintained and protects the heat material from the impact of high temperature processes.

3. Ferrics should not put things in the fuel that lower the energy provided by coal such as chlamyd or lime.

4. When the oven is running smoothly, cooling the oven with air and keeping humidity low will help preserve energy by saving extra heating.

Samples and Equipment you need for Low-Temperature Sludge Drying

Application Scenarios:

- Treatment plants for wastewater can be found in cities.

- They have been created to handle Industrial wastewater.

- They work well in cities and factories as they avoid outdoors, are easy to use and save power.

Equipment Selection:

• Paddle-Type Dryer: This Kind of Dryer Uses a Paddle to Move the Mud through the Jacket Shaft which Can Process Various Types of Mud.

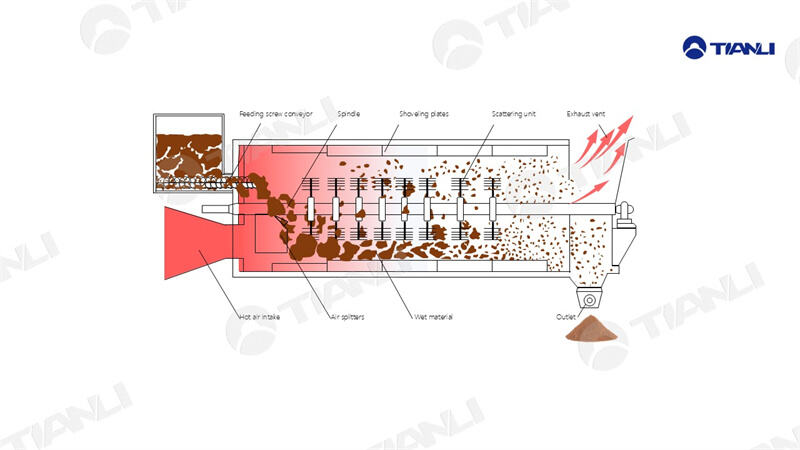

• Rotary Dryer: The machinery uses rotating bars to promote quick heat treatment; Use this dryer for materials like soybeans, requiring rapid drying, if it has a moisture level from 70 to 85 percent.

Priority for Rotary Dryers:

- The ability to work with moisture and lots of materials between 70 and 85%.

- There are many rooms where HVAC unit can be fitted.

- For increase in energy consumption and dust control, the product requires rapid drying.

Priority for Paddle-Type Dryers:

• The moisture in mud is more than 85% or it is considered very viscous (chemical or food processing mud).

• Standards about environmental protection (low amounts of dust in the air and VOC) are very rigid.

• In limited location areas may require to fit boilers and seek energy-saving options.

• Should be produced as equally as possible and reduce the need for further procedure.

Significance of Sludge Incineration Coupled with Power Generation

Since urban and industrial sludge is increasing and now it is more complex, it is important to deal with its disposal and use. The main advantage of consuming is that it greatly reduces waste, eliminates the breakdown of organic parts and solids heavy metals. With significant resources for a lot of heat and strong furnaces, industrial functions can use resources properly, reduce the remaining and ensure safety by using sludge for drying and heating.

Shandong Tianli Energy Company, Ltd., has created various techniques to mix mud with coal during the power plant operation. In this process harvesting energy improves calorie value of sludge which works well in many situations. It cuts mud, dumping does not cause secondary pollution, helps clean the city, works for ecological development, supports recycling and improves the competition of the area.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK

UZ

UZ