There are not any industries also in which rotary furnaces take part just they and used for melting metals. The metalworking industry is a great site to find rotary type furnaces. This industry also is where workers melt scrap metal by use of a rotary furnace. They collect old metal things and convert them into new metal objects which can be used for other works of use.

The forging of metal is where stuff produced from metallic, the same as Shandong Tianli's pneumatic conveying dryer. Melting and shaping the metal is no easy task. Rotary furnaces, however, take a lot of that effort away. Metalworkers use them in order to melt metals faster and at lower cost. How this Shift Affects the Metal Industry With a more rapid melt rate, production of metal items becomes simpler and quicker which is beneficial for industries.

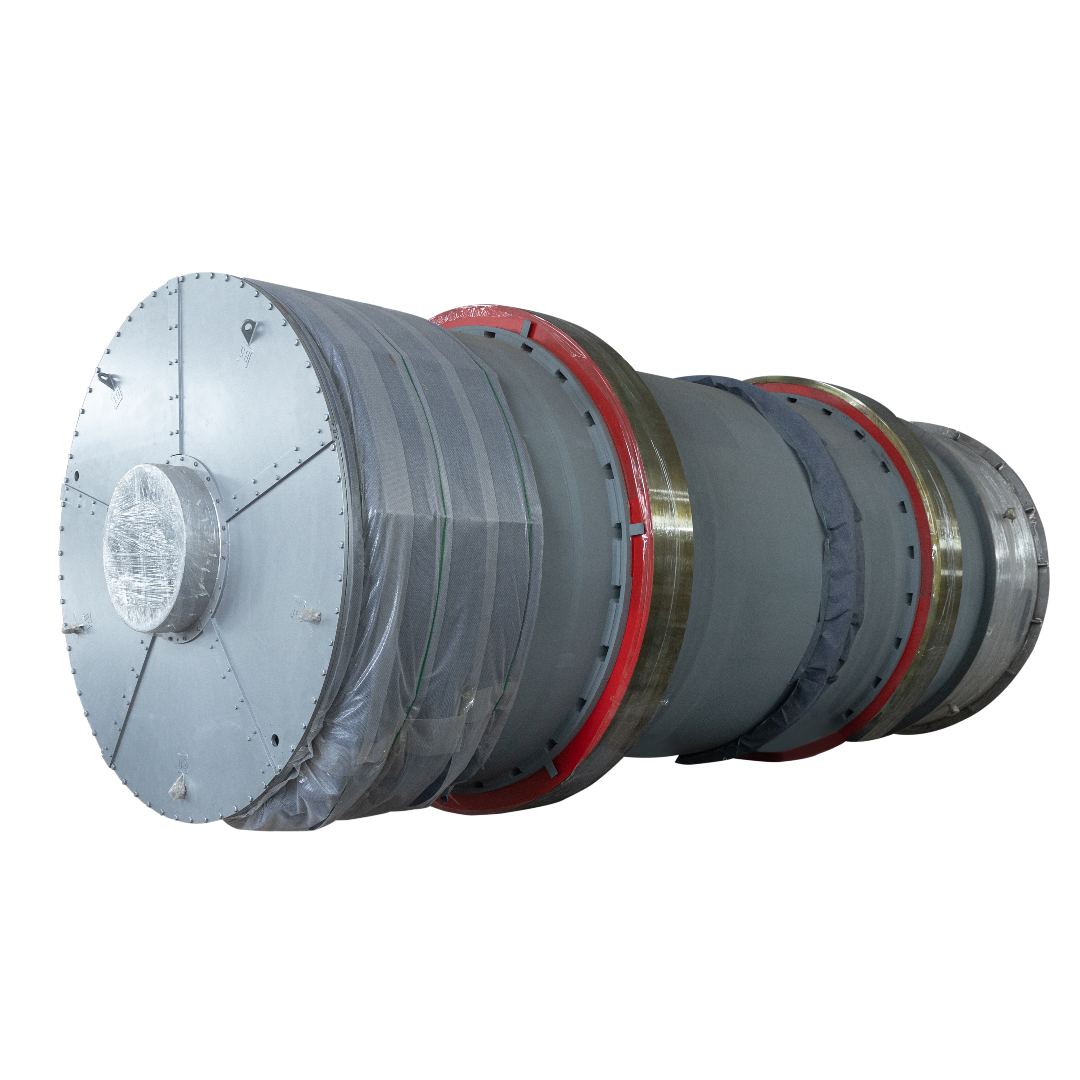

Rotary Furnaces for Metalworking technique is efficient in many aspects, also the pressure nozzle spray dryer from Shandong Tianli. The most significant advantage is that they are energy saving. Rotary furnace are also called as Rotary Kiln. It is use for provide soft heat treatment in fluid energy form which gives a better yield than older traditional furnaces with less power consumption requirements (less energy). Not only does this save energy (and help the environment), it also means companies end up spending less on using them.

The melting process is improved in rotary furnaces Rotary Furnace For Dross The design of these furnaces allows the metal to melt smoothly and at a perfect temperature. Metal melting is a very important process to be done properly cause it makes the product have more quality. The receipt of stronger and more durable finished metal items is what customers require.

In the chemical processing sector, rotary furnaces are invaluable as they have a very broad applicability for types of material handled, as well as the Shandong Tianli's rotary calciner. The traditional furnaces can do nothing beyond this material, whereas they have the ability to melt and handle things that are not achievable from other melting processes. The combinatory power has also resulted in numerous new ideas and chemical processing technologies that have grown the industry.

Rotary furnaces also have a significant role in the recycling sector, the same as industrial drum dryer manufactured by Shandong Tianli. They employ furnaces that melt scrap as a part of the steel recycling process, producing new metal products. Well, of course it is for the earth sake as we are slowly killing our planet with waste. Rather than trash your olf metal, we can recycle it and make a whole new masterpiece.

Considering they occupy a much larger role in respect to metal recycling, rotary furnaces are also very adaptable machines, also the Shandong Tianli's product such as rotary dryer cost. Many of the materials you can process are not even technically scrap metal. This adaptability makes them very effective equipment in the recycling sector, helping companies to decide on a larger variety of items meanwhile.

Tianli, the leading enterprise of China's drying industry is a major national high-tech company, Shandong Gazelle Enterprise and an example enterprise for "Scitech Innovation and Reform". Tianli is home to an RD Center and close to 150 engineers. The company also has a Design Center of Class A that has excellent capability in Rotary furnace design. 3. Provide customers with high-value services, focusing on and solving problems from the perspective of customers, and provide assistance to customers in the areas of technological development, pilot test, process design, manufacturing of products, installation and commissioning, after-sales service as well as technology upgrades. 4. Tianli has been able to successfully complete more than 3, 300 projects across China.

1 Quality Control: A mature quality system is crucial to ensure the quality of the products 2 Timeline guarantee: Tianli has a 70 000 square meters of equipment manufacturing facility with an Rotary furnace of five hundred tons It is able to adapt production plans to demands of customers and maintain the timeline 3 Our equipment can meet the high-end market requirements and guarantee quality by selecting items that are precisely 4 Innovation in technology: concentrate on innovation and research in the field of technology constantly develop new technologies and improve manufacturing processes and ensure market competitiveness

Tianli holds more than 240 patents and a number of key technologies and products, each with the rights to their Rotary furnace. Tianli was awarded the prestigious Outstanding Achievement Award for the "Ninth Five Year Plan" National Key Science and Technology Research Plan. The plan also received the first prize as well as four second prizes, and three third prizes in the Shandong Provincial Science and Technology Progress Award. Tianli was involved in the development and publication of five books and monographs relating to the standard. 3. Tianli's RD Center and Innovation System create a positive cycle from the latest technological advances to engineering solutions and massive sets of complete drying equipment. This will ensure the continued growth of the company.

Rotary furnace has a top-quality brand cultivation enterprise located in Shandong Province and a Shandong Famous Brand. Tianli is referred to as "The First (Set of) Technical Equipment Manufacturing Enterprise of Shandong Province", Single Champion Enterprise of Manufacturing Industry of Shandong Province etc. 2. Tianli's project experience is a huge asset. It has completed more than 3, 000 projects, including in new materials, energy biochemicals, petrochemicals and biochemicals metallurgical, and other industries.